In industrial piping systems, pipe tees are crucial fittings for achieving media diversion or convergence.

ASME B16.9 is one of the most widely used global standards for buttweld fittings, providing standardized specifications for key geometric dimensions of tees, elbows, reducers, and other fittings.

ASME B16.9 – Factory-Made Wrought Buttwelding Fittings

NPS 1/2″ – 48″

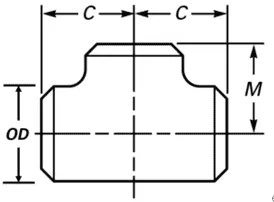

Equal Tee

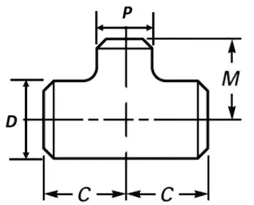

Reducing Tee

Pipe Caps, etc.

Three ports with the same nominal size

Main pipe and branch pipe diameters are the same

Suitable for symmetrical flow distribution systems

Common representation:

NPS 6 × 6 × 6 Equal Tee

Main pipe size is the same, branch pipe size is smaller

Used for systems with different flow rates or pressures

Common representation:

NPS 8 × 8 × 4 Reducing Tee

|

ASME B16.9 Pipe Tee Dimensions |

|

||

|

NOMINAL PIPE SIZE |

OUTSIDE DIAMETER |

CENTER TO END |

LENGTH |

|

inch. |

OD mm |

C mm |

M mm |

|

1/2 |

21.3 |

25 |

25 |

|

3/4 |

26.7 |

29 |

29 |

|

1 |

33.4 |

38 |

38 |

|

1 1/4 |

42.2 |

48 |

48 |

|

1 1/2 |

48.3 |

57 |

57 |

|

2 |

60.3 |

64 |

64 |

|

2 1/2 |

73 |

76 |

76 |

|

3 |

88.9 |

86 |

86 |

|

3 1/2 |

101.6 |

95 |

95 |

|

4 |

114.3 |

105 |

105 |

|

5 |

141.3 |

124 |

124 |

|

6 |

168.3 |

143 |

143 |

|

8 |

219.1 |

178 |

178 |

|

10 |

273.1 |

216 |

216 |

|

12 |

323.9 |

254 |

254 |

|

14 |

355.6 |

279 |

279 |

|

16 |

406.4 |

305 |

305 |

|

18 |

457.2 |

343 |

343 |

|

20 |

508 |

381 |

381 |

|

22 |

559 |

419 |

419 |

|

24 |

610 |

432 |

432 |

|

26 |

660 |

495 |

495 |

|

28 |

711 |

521 |

521 |

|

30 |

762 |

559 |

559 |

|

32 |

813 |

597 |

597 |

|

34 |

864 |

635 |

635 |

|

36 |

914 |

673 |

673 |

|

38 |

965 |

711 |

711 |

|

40 |

1016 |

749 |

749 |

|

42 |

1067 |

762 |

711 |

|

44 |

1118 |

813 |

762 |

|

46 |

1168 |

851 |

800 |

|

48 |

1219 |

889 |

838 |

|

ASME B16.9 Pipe Tee Dimensions |

||||

|

NOMINAL PIPE SIZE |

OUTSIDE DIAMETER |

CENTER TO END |

||

|

Inch |

D mm |

P mm |

C mm |

M mm |

|

1/2 x 3/8 |

21.3 |

17.1 |

25 |

25 |

|

1/2 x 1/4 |

21.3 |

13.7 |

25 |

25 |

|

3/4 x 1/2 |

26.7 |

21.3 |

29 |

29 |

|

3/4 x 3/8 |

26.7 |

17.1 |

29 |

29 |

|

1 x 3/4 |

33.4 |

26.7 |

38 |

38 |

|

1 x 1/2 |

33.4 |

21.3 |

38 |

38 |

|

1 1/4 x 1 |

42.2 |

33.4 |

48 |

48 |

|

1 1/4 x 3/4 |

42.2 |

26.7 |

48 |

48 |

|

1 1/4 x 1/2 |

42.2 |

21.3 |

48 |

48 |

|

1 1/2 x 1 1/2 |

48.3 |

42.2 |

57 |

57 |

|

1 1/2 x 1 |

48.3 |

33.4 |

57 |

57 |

|

1 1/2 x 3/4 |

48.3 |

26.7 |

57 |

57 |

|

1 1/2 x 1/2 |

48.3 |

21.3 |

57 |

57 |

|

2 x 1 1/2 |

60.3 |

48.2 |

64 |

60 |

|

2 x 1 1/4 |

60.3 |

42.2 |

64 |

57 |

|

2 x 1 |

60.3 |

33.4 |

64 |

51 |

|

2 x 3/4 |

60.3 |

26.7 |

64 |

44 |

|

2 1/2 x 2 |

73 |

60.3 |

76 |

70 |

|

2 1/2 x 1 1/2 |

73 |

48.3 |

76 |

67 |

|

2 1/2 x 1 1/4 |

73 |

42.2 |

76 |

64 |

|

2 1/2 x 1 |

73 |

33.4 |

76 |

57 |

|

3 x 2 1/2 |

88.9 |

73 |

86 |

83 |

|

3 x 2 |

88.9 |

60.3 |

86 |

76 |

|

3 x 1 1/2 |

88.9 |

48.3 |

86 |

73 |

|

3 x 1 1/4 |

88.9 |

42.2 |

86 |

70 |

|

3 1/2 x 3 |

101.6 |

88.9 |

95 |

92 |

|

3 1/2 x 21/2 |

101.6 |

73 |

95 |

89 |

|

3 1/2 x 2 |

101.6 |

60.3 |

95 |

83 |

|

3 1/2 x 1 1/2 |

101.6 |

48.3 |

95 |

79 |

|

4 x 3 1/2 |

114.3 |

101.6 |

105 |

102 |

|

4 x 3 |

114.3 |

88.9 |

105 |

98 |

|

4 x 2 1/2 |

114.3 |

73 |

105 |

95 |

|

4 x 2 |

114.3 |

60.3 |

105 |

89 |

|

4 x 1 1/2 |

114.3 |

48.3 |

105 |

86 |

|

5 x 4 |

141.3 |

114.3 |

124 |

117 |

|

5 x 3 1/2 |

141.3 |

101.6 |

124 |

114 |

|

5 x 3 |

141.3 |

88.9 |

124 |

111 |

|

5 x 2 1/2 |

141.3 |

73 |

124 |

108 |

|

5 x 2 |

141.3 |

60.3 |

124 |

105 |

|

6 x 5 |

168.3 |

141.3 |

143 |

137 |

|

6 x 4 |

168.3 |

114.3 |

143 |

130 |

|

6 x 3 1/2 |

168.3 |

101.6 |

143 |

127 |

|

6 x 3 |

168.3 |

88.9 |

143 |

124 |

|

6 x 2 1/2 |

168.3 |

73 |

143 |

121 |

|

8 x 6 |

219.1 |

168.3 |

178 |

168 |

|

8 x 5 |

219.1 |

141.3 |

178 |

162 |

|

8 x 4 |

219.1 |

114.3 |

178 |

156 |

|

8 x 3 1/2 |

219.1 |

101.6 |

178 |

152 |

|

10 x 8 |

273.1 |

219.1 |

216 |

203 |

|

10 x 6 |

273.1 |

168.1 |

216 |

194 |

|

10 x 5 |

273.1 |

141.3 |

216 |

191 |

|

10 x 4 |

273.1 |

114.3 |

216 |

184 |

|

12 x 10 |

323.9 |

273.1 |

254 |

241 |

|

12 x 8 |

323.9 |

219.1 |

254 |

229 |

|

12 x 6 |

323.9 |

168.3 |

254 |

219 |

|

12 x 5 |

323.9 |

141.3 |

254 |

216 |

|

14 x 12 |

355.6 |

323.9 |

279 |

270 |

|

14 x 10 |

355.6 |

273.1 |

279 |

257 |

|

14 x 8 |

355.6 |

219.1 |

279 |

248 |

|

14 x 6 |

355.6 |

168.3 |

279 |

238 |

|

16 x 14 |

406.4 |

355.6 |

305 |

305 |

|

16 x 12 |

406.4 |

323.9 |

305 |

295 |

|

16 x 10 |

406.4 |

273.1 |

305 |

283 |

|

16 x 8 |

406.4 |

219.1 |

305 |

273 |

|

16 x 6 |

406.4 |

168.3 |

305 |

264 |

|

18 x 16 |

457 |

406.4 |

343 |

330 |

|

18 x 14 |

457 |

355.6 |

343 |

330 |

|

18 x 12 |

457 |

323.9 |

343 |

321 |

|

18 x 10 |

457 |

273.1 |

343 |

308 |

|

18 x 8 |

457 |

219.1 |

343 |

298 |

|

20 x 18 |

508 |

457 |

381 |

368 |

|

20 x 16 |

508 |

406.4 |

381 |

356 |

|

20 x 14 |

508 |

355.6 |

381 |

356 |

|

20 x 12 |

508 |

323.9 |

381 |

346 |

|

20 x 10 |

508 |

273.1 |

381 |

333 |

|

20 x 8 |

508 |

219.1 |

381 |

324 |

|

22 x 20 |

559 |

508 |

419 |

406 |

|

22 x 18 |

559 |

457 |

419 |

394 |

|

22 x 16 |

559 |

406.4 |

419 |

381 |

|

22 x 14 |

559 |

355.6 |

419 |

381 |

|

22 x 12 |

559 |

323.9 |

419 |

371 |

|

24 x 10 |

559 |

273.1 |

419 |

359 |

|

24 x 22 |

610 |

559 |

432 |

432 |

|

24 x 20 |

610 |

508 |

432 |

432 |

|

24 x 18 |

610 |

457 |

432 |

419 |

|

24 x 16 |

610 |

406.4 |

432 |

406 |

|

24 x 14 |

610 |

355.6 |

432 |

406 |

|

24 x 12 |

610 |

323.9 |

432 |

397 |

|

24 x 10 |

610 |

273.1 |

432 |

384 |

The wall thickness of the tee is determined by the schedule of the steel pipe it is fitted with (Sch 20 / 40 / 80 / XS / XXS).

The common bevel angle is 37.5° (ASME B16.25).

It offers superior strength and fluid performance, and is more commonly used in oil and gas projects.

Pay attention to manufacturing tolerances and delivery time.

They are usually hot-pressed or molded.

ASTM A234 WPB → Carbon steel tee

ASTM A403 WP304/316 → Stainless steel tee

ASTM A420 WPL6 → Low-temperature tee

Yes, provided the material, wall thickness, and design pressure meet ASME B31.3 / B31.4 / B31.8 requirements.

SP-75 is mainly used for high-strength, large-diameter oil and gas pipelines, while B16.9 is more universal.

Yes, but it must be specified as "Non-standard" and drawings must be provided for confirmation.