In modern industrial piping systems, pipe flanges play a crucial role as indispensable connecting components. Whether in petrochemical, power, water supply and drainage, or food and pharmaceutical industries, flanges are ubiquitous wherever pipeline transportation is involved. This article will detail the structure, types, sealing methods, and marking methods of flanges, providing authoritative reference for engineering design and procurement.

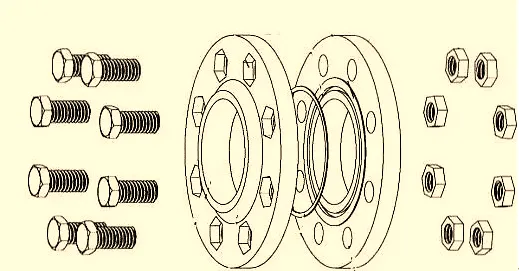

A flange is typically disc-shaped with bolt

holes on its outer circumference and a central opening for the pipe or

equipment to pass through.

During installation, two flanges are placed

opposite each other, a gasket is placed between them, and bolts are passed

through the bolt holes and tightened, thus tightly connecting the pipe or

equipment and ensuring that the medium inside the pipeline does not leak. It

also provides a certain degree of support and positioning for the piping

system.

The choice of different materials depends

on factors such as the characteristics of the medium inside the pipeline, the

working pressure, and the temperature.

For example, stainless steel flanges are

often used in chemical pipelines transporting highly corrosive media; while

carbon steel flanges are sufficient for ordinary water pipeline systems.

Common pipe flanges include slip-on

flanges, weld neck flanges, socket flanges, loose flanges, and threaded

flanges.

Slip-on flanges are divided into plate

slip-on flanges and neck slip-on flanges. They have a simple structure and low

cost, and are suitable for pipe connections with relatively low pressure and

small diameter.

They are widely used in general civil

building water supply and drainage and low-pressure industrial pipelines.

Socket flanges are suitable for

small-diameter pipes. The pipe is inserted into the socket of the flange and

welded, resulting in a strong connection and good sealing performance.

Weld neck flanges are connected to the pipe

by butt welding. The weld quality is high, and they can withstand higher

pressure and temperature.

They are commonly used in high-temperature

and high-pressure pipeline systems in industries such as petrochemicals and

power.

Loose flanges are characterized by not

being directly welded to the pipe, but rather connected via flanges, steel

rings, or other connecting parts.

They are suitable for non-ferrous metal

pipelines or applications requiring frequent disassembly, reducing damage to

the pipe base material.

Threaded flanges connect to pipes using

threads, making installation and disassembly convenient.

They are generally used in piping systems

with low pressure, small pipe diameter, and frequent maintenance requirements.

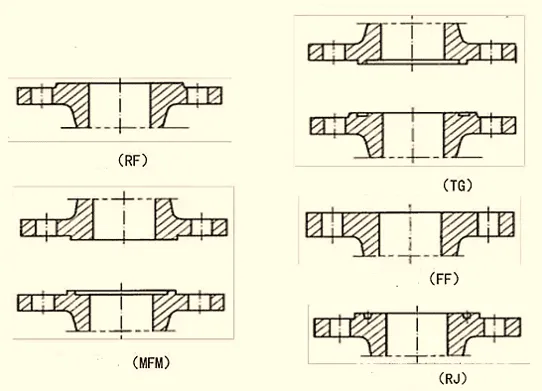

Flange sealing surfaces are classified as

flat face (FF), raised face (RF), male and female face (MFM), tongue and groove

(TG), and ring joint (RJ).

The sealing surface is a smooth plane,

suitable for low pressure and non-toxic media, generally used for water

pipelines and other connections with low requirements.

Also known as a flat face flange, the

sealing surface is flat, resulting in a large contact area with the gasket.

After pre-tightening, the gasket can easily extend or move to the sides,

resulting in poor sealing performance. It is only suitable for low-pressure

applications.

Consists of a concave face and a convex

face. They must be used in conjunction with a convex face during installation.

This type of flange offers better sealing

performance than a flat face flange and is commonly used for medium-pressure

pipeline connections carrying toxic or hazardous media.

The sealing surface consists of a tongue

and a groove, providing excellent sealing performance.

It is generally used for connections of

flammable, explosive, toxic media, and high-pressure pipelines.

A ring joint seal flange has an annular

trapezoidal groove cut into the flange's raised face as the sealing surface.

Like

the tongue and groove seal, the flange must be axially separated during

installation and disassembly. The possibility of axial separation of the flange

must be considered in pipeline design.

This sealing surface is specifically

designed to mate with solid metal gaskets machined into octagonal or elliptical

shapes to achieve a sealed connection. It offers good sealing performance,

requires strict installation, and is suitable for high-temperature and

high-pressure conditions, but demands high precision in sealing machining.

The outer ring or near the sealing surface

of the flange usually displays the following key information:

This indicates the diameter of the pipe to

which the flange will connect, usually in millimeters (mm). For example,

"DN100" indicates that the flange is suitable for pipes with a

nominal diameter of 100 mm.

This indicates the design pressure the flange can withstand, commonly measured in megapascals (MPa) or pounds per square inch (psi). For example, "PN16" indicates a nominal pressure of 16 bar.

American Standard flanges use the CLASS

designation, such as "CLASS 150," indicating a pressure rating of 150

pounds.

The flange material determines its

strength, corrosion resistance, and applicable environment. Common material

designations include:

Carbon steel: such as "A105,"

indicating forged carbon steel.

Stainless steel: such as "304" or

"316," representing different types of stainless steel.

Alloy steel: such as "F22,"

indicating low-alloy steel.

Flanges must be designed and manufactured

to conform to specific standards, such as:

ANSI/ASME B16.5: American Standard flange.

EN 1092-1: European Standard flange.

GB/T 9119: Chinese National Standard

flange.

Some flanges will indicate the heat

treatment process, such as "N" (normalizing) or "QT"

(quenching and tempering).

Selecting the appropriate flange type and

sealing method is a crucial step in ensuring safety, durability, and economy in

piping system design.

Low-pressure, non-hazardous media → Slip-on or threaded flanges, flat or raised face seals;

High-pressure, high-temperature, or

hazardous media → Butt-welded, tongue and groove, or

ring face flanges, stainless steel or alloy steel.

Scientific and reasonable flange selection

can significantly reduce pipeline leakage risks and maintenance costs, and

improve project reliability.