In the production and use of seamless pipes, flaw detection is a crucial step in ensuring product quality and safety. As a fundamental material in the industrial field, the quality of seamless steel pipes directly affects equipment safety and service life.

Eddy current testing is mainly used for

surface and near-surface flaw detection. Through-type eddy current testing

primarily detects transverse defects and delamination. Eddy currents can also

be used for thickness measurement, hardness, strength measurement, diameter

measurement, and distance measurement. Acceptance levels are A and B.

Acceptance level A can be used as an alternative to water pressure tightness

testing, while acceptance level B is negotiated between the supplier and the

buyer and specified in the contract. Sample pipes include drilled holes

(through holes) and longitudinal grooves.

Eddy current testing is suitable for

detecting surface and near-surface defects in seamless steel pipes made of

conductive materials.

When an alternating magnetic field

approaches a conductive seamless steel pipe, eddy currents are generated inside

the pipe. If defects exist on or near the surface of the seamless steel pipe,

they will affect the distribution and magnitude of the eddy currents. The

presence of defects is determined by detecting changes in the eddy currents.

Fast detection speed, enabling automated

inspection; high sensitivity for surface and near-surface defects; capable of

inspecting seamless tubes made of various conductive materials.

Qualitative and quantitative analysis of

defects is relatively difficult; poor inspection results for seamless tubes

with complex shapes; limited detection depth.

Internal and external wall cracks,

longitudinal cracks, transverse cracks, network cracks, stress corrosion

cracks, fatigue cracks, manufacturing defect cracks, weld heat-affected zone

cracks, service damage cracks, buried cracks, etc.

Pitting depth, uniform corrosion area,

local thinning, erosion pits, selective corrosion, crevice corrosion, microbial

corrosion, weld corrosion, heat-affected zone corrosion, wall thickness

reduction rate, etc.

Inclusions, delamination, folds, porosity,

looseness, white spots, coarse grains, segregation, forging cracks, rolling

defects, etc.

Incomplete fusion, incomplete penetration,

undercut, weld beads, concave or convex welds, misalignment, excessive weld

reinforcement, weld cracks, porosity, and slag inclusions.

Nominal wall thickness, minimum remaining

wall thickness, average wall thickness, wall thickness reduction, ellipticity,

out-of-roundness, local thickening, corrosion allowance, wall thickness

distribution map, wall thickness variation rate, etc.

Subcutaneous cracks, near-surface porosity,

delamination, folds, near-weld defects, heat treatment cracks, grinding cracks,

quenching cracks, extrusion cracks, near-surface corrosion, etc.

Coating thickness, coating peeling, coating

porosity, lining fit, lining cracks, anti-corrosion layer damage, lining

thinning, coating adhesion, lining corrosion, interface defects, etc.

Pipe outer diameter, pipe inner diameter,

curvature, straightness, ellipticity, circumference, cross-sectional shape,

beveling angle, pipe end preparation, length deviation, etc.

Electrical conductivity, magnetic

permeability, hardness, grain size, heat treatment state, material grade

identification, microstructure, non-metallic inclusions, decarburized layer,

hardened layer depth, etc.

Remaining service life, safety status,

damage level, failure risk, applicability, inspection cycle, maintenance

recommendations, service life prediction, risk level, conditions for continued

use, etc.

Through-type eddy current testing is the most widely used method for eddy

current testing of steel pipes. It is generally used for steel pipes with a

diameter less than 180mm. Its advantages include fast testing speed, the

ability to inspect the entire surface of the steel pipe, and relatively simple

equipment adjustment and operation.

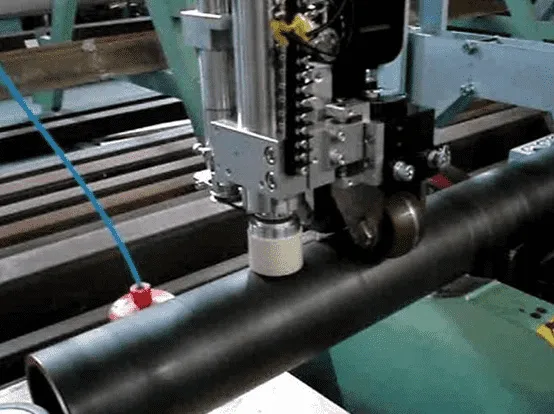

Rotating point probe eddy current testing

is an automated flaw detection method where a network of point probes rotates

around a steel pipe, while the pipe moves linearly. The point probes are placed

inside a rotating head, and the probes rotate to scan the surface of the steel

pipe.

The rotating point probe method is more

suitable for inspecting small to medium diameter steel pipes. The point probes

have high sensitivity and are suitable for inspecting steel pipes with

relatively smooth surfaces. It is not suitable for hot-rolled steel pipes,

steel pipes with oxide scale, or other rough surfaces.

ISO 15549, ISO 15548-1, ISO 15548-2, ISO

12718, ISO 20669, ASME BPVC SJianCeion V, ASME B31.3, ASTM E309, ASTM E571,

ASTM E1316, EN 1711, EN 13860-1, EN 13860-2, JIS G 0588, GB/T 12604.6, GB/T

14480, GB/T 26953, GB/T 26954, GB/T 28705, GB/T 28706, GB/T 32538, GB/T 32565,

GB/T 34361, GB/T 34634, GB/T 38894, JB/T 4730.6, JB/T 6912, NB/T 47013.6

Capable of simultaneous multi-frequency

excitation and signal processing, it can simultaneously detect defects of

different depths, suppress interference signals, and improve the

signal-to-noise ratio. Suitable for defect detection and classification under

complex working conditions.

Utilizes far-field eddy current technology

to detect defects across the entire wall thickness of ferromagnetic pipes.

Unaffected by the skin effect, it can detect defects on both the inner and

outer walls of pipes, suitable for oil and gas pipeline inspection.

Composed of multiple detection coils

arranged according to specific rules, it can cover a large detection area at

once, improving detection efficiency and generating two-dimensional or

three-dimensional images of pipe defects for easy defect location and

assessment.

Performs magnetic saturation treatment on

ferromagnetic materials to eliminate the influence of changes in material

permeability on eddy current detection, improving detection accuracy and

reliability. Suitable for pipes made of magnetic materials such as carbon steel

and alloy steel.

Integrating an eddy current testing system

and an automated movement device, this robot can autonomously move and inspect

pipes inside, suitable for long-distance, large-diameter, and inaccessible

pipelines.

Utilizing digital signal processing

technology, this system filters, amplifies, performs phase analysis, and

displays impedance planes on the detection signal, improving defect

identification and quantitative accuracy.

Specially designed for pipeline inspection

in high-temperature environments, this equipment features high-temperature

resistant probes and cables, allowing for online inspection while the system is

running, minimizing downtime.

Includes various types such as absolute

probes, differential probes, reflective probes, and through-type probes,

optimized for different pipeline specifications, materials, and inspection

requirements.

Enables precise positioning and uniform

speed movement of the probe on the pipeline surface, ensuring comprehensive and

consistent inspection coverage. Suitable for rapid inspection of large batches

of regularly shaped pipelines.

This system collects, stores, and processes

inspection data in real time, generates inspection reports, establishes a

pipeline inspection database, enables historical data comparison and trend

analysis, and supports pipeline integrity management.

In conclusion, eddy current testing plays a crucial role in the production and quality control of

seamless pipes. It can improve product quality, ensure production safety,

and optimize production processes, thus possessing significant practical

application value.