Seamless steel pipes play a crucial role in industrial production, infrastructure construction, and numerous engineering fields. Their unique structural characteristics, excellent mechanical properties, and wide range of applications make them an indispensable raw material for many industries.

However, long-term use and harsh

environmental conditions often cause varying degrees of damage and wear to

seamless steel pipes, thus affecting their service life and safety.

Therefore, understanding and mastering the

repair and maintenance technology of seamless steel pipes is of great

significance for extending their service life and ensuring engineering safety.

This article will explore the repair and maintenance methods of seamless steel

pipes in depth.

The types of damage to seamless steel pipes

are diverse, mainly including corrosion, wear, cracks, and deformation. These

damages not only reduce the strength and sealing performance of the steel pipe

but may also cause safety hazards.

Corrosion is one of the most common types

of damage to seamless steel pipes. In humid, acidic, or alkaline environments,

the surface of the steel pipe is prone to chemical reactions, leading to

corrosion.

Corrosion not only reduces the wall

thickness and strength of the steel pipe but may also cause perforation and

leakage.

Wear refers to the gradual wear and

thinning of the surface of a seamless steel pipe during use due to friction.

The degree of wear depends on the magnitude

of the friction force, the duration of friction, and the material of the steel

pipe. Severely worn steel pipes will experience a significant decrease in

strength and sealing performance.

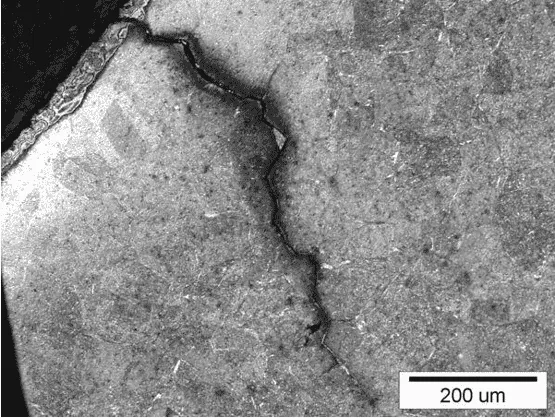

Cracks are another common type of damage to

seamless steel pipes. Cracks may be caused by stress concentration, fatigue,

impact, or improper heat treatment.

The presence of cracks significantly

reduces the strength and toughness of the steel pipe, and may even lead to

fracture.

Deformation refers to the change in shape

of a seamless steel pipe during use due to external forces or temperature

changes.

Deformation not only affects the geometric

dimensions and sealing performance of the steel pipe, but may also cause stress

concentration and cracks.

Different repair techniques are required

for different types of damage to seamless steel pipes. The following are some

common seamless steel pipe repair methods:

Welding repair is a commonly used method

for repairing seamless steel pipes. For localized damage such as cracks and

perforations, welding techniques can be used for repair.

Welding repair offers advantages such as

high strength, good sealing, and wide applicability. However, the welding

process generates high temperatures and stress, requiring strict control of

welding parameters and processes to avoid secondary damage to the steel pipe.

Spray coating repair is a method suitable

for repairing corrosion and wear on the surface of seamless steel pipes. By

spraying corrosion-resistant and wear-resistant coatings, the protective layer

on the steel pipe surface can be restored, improving its corrosion resistance

and wear resistance.

Spray coating repair offers advantages such

as convenient construction, low cost, and wide applicability. However, the

thickness and adhesion of the sprayed layer need to be strictly controlled to

ensure the repair effect.

Wrapping repair is a method suitable for

repairing large-area damage or deformation of seamless steel pipes. By wrapping

corrosion-resistant, high-strength materials (such as fiberglass, carbon fiber,

etc.), the shape and strength of the steel pipe can be restored.

Wrapping repair offers advantages such as

fast construction speed, no production downtime, and the ability to operate

under pressure. However, wrapping repair requires strict control of the

thickness and tension of the wrapping layer to ensure the repair effect.

Tube expansion repair is a method suitable

for repairing deformed and reduced-diameter seamless steel pipes. By using

expansion tools to partially or completely expand the steel pipe, its original

size and shape can be restored.

Tube expansion repair has advantages such

as convenient construction, no production shutdown required, and on-site

operation. However, the expansion pressure and expansion amount must be

strictly controlled during the expansion process to avoid excessive damage to

the steel pipe.

Composite material repair is a new type of

seamless steel pipe repair method. By bonding composite materials (such as

epoxy resin, glass fiber, etc.) to the damaged area of the steel

pipe, a new protective layer can be formed, improving the strength and corrosion

resistance of the steel pipe.

Composite material repair has advantages

such as convenient construction, low cost, and wide applicability. However, the

performance and lifespan of the composite material need to be strictly

controlled to ensure the repair effect.

To solve the problem of repairing damaged

seamless steel pipes, experts at home and abroad have developed a brand-new

non-destructive repair method—composite material

reinforcement technology.

Composite materials are artificially

synthesized high-strength materials, made up of many materials with different

structures bonded together through specific processes. It boasts advantages

such as light weight, high strength, corrosion resistance, and wear resistance,

meeting the requirements of harsh operating environments.

1. For damaged seamless steel pipes,

cleaning, coating, and environmental remediation are necessary to achieve

optimal construction conditions;

2. Apply a specialized composite material

around the damaged area, simultaneously strengthening the pipe's support to

achieve reinforcement;

3. Through a specific pressure control

system, strengthen the adhesion between the composite material and the pipe,

completing non-destructive repair of the pipeline.

Composite material reinforcement technology

is applicable to many fields, such as petrochemicals, water conservancy, and

heating. It is important to note that this technology is not suitable for pipes

with excessively large damaged areas or pipes with insufficient strength.

Besides repair techniques, the maintenance

of seamless steel pipes is equally important. Regular maintenance and upkeep

can extend the service life of the steel pipes and ensure their normal

operation. The following are some common seamless steel pipe maintenance

methods:

Regular inspection is the foundation of

seamless steel pipe maintenance. Regularly inspecting the appearance, wall

thickness, and sealing performance of steel pipes can help identify and address

potential safety hazards promptly.

It is recommended to conduct a

comprehensive inspection at least once a year, with a specific inspection plan

developed based on actual conditions.

Cleanliness and maintenance are crucial for

maintaining the good condition of seamless steel pipes. Regularly removing

dirt, grease, and corrosion products from the pipe surface can slow down

corrosion and extend service life.

Additionally, painting or spraying

protective agents can improve the pipe's corrosion resistance and aesthetics.

Corrosion protection treatment is an

effective method for preventing corrosion of seamless steel pipes. Using

corrosion-resistant coatings, hot-dip galvanizing, sandblasting, and other

anti-corrosion technologies can form a protective layer on the pipe surface,

isolating it from contact with corrosive media.

It is recommended to perform anti-corrosion

treatment before putting new steel pipes into use, with a specific

anti-corrosion plan developed based on actual conditions.

Overloading is a major cause of damage to

seamless steel pipes. Therefore, when using seamless steel pipes, their design

parameters and operating range should be strictly adhered to, and overloading

should be avoided. Simultaneously, monitoring and inspection of steel pipes

should be strengthened to promptly detect and address any abnormalities.

Proper storage and transportation are

crucial for protecting seamless steel pipes from damage. When storing steel

pipes, suitable sites and environmental conditions should be selected to avoid

direct sunlight, rain, and moisture.

During transportation, effective securing

and protective measures should be taken to prevent the steel pipes from being

impacted or squeezed.

Seamless steel pipes are one of the

important raw materials in industrial production. Their repair and maintenance

are of great significance for extending their service life and ensuring project

safety.

By understanding and mastering the types

and causes of damage to seamless steel pipes, repair techniques, and

maintenance methods, we can better address the problems and challenges that may

be encountered during the use of seamless steel pipes.

At the same time, we should also pay

attention to the details and techniques in actual operation to ensure the

quality and effectiveness of repair and maintenance work.