LSAW Steel Pipe

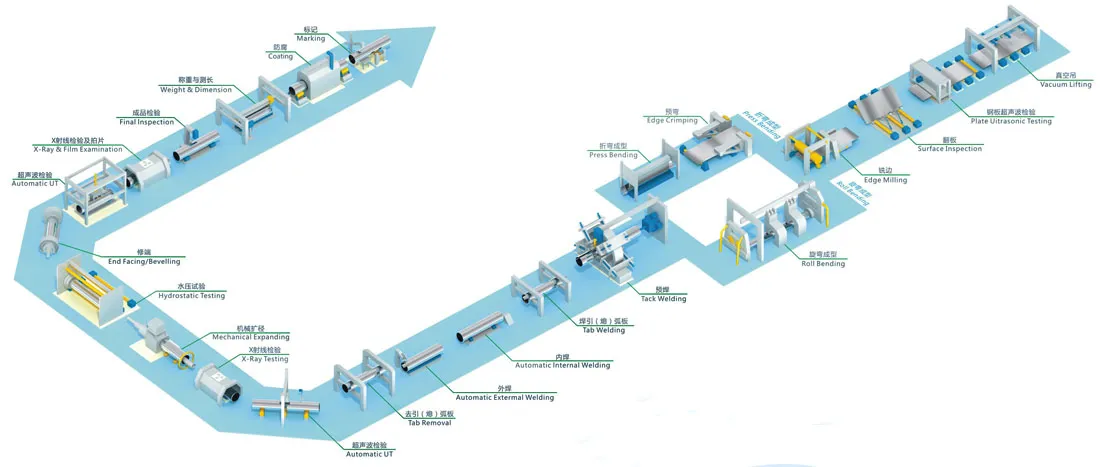

Straight seam submerged arc welded pipe (LSAW) is a welded steel pipe manufactured by submerged arc welding (SAW) process, and the weld direction is parallel to the axis of the steel pipe (i.e. longitudinal welding). The process forms a high-strength and high-sealing steel pipe by pre-bending the steel plate into a tube shape and then automatically submerging arc welding under the protection of the flux layer.

Huaxi Steel LSAW pipe has made many breakthroughs in ultra-thick wall and ultra-large diameter, and is very competitive in the Chinese market.

Product Range

Outer diameter: Φ508mm- 3048mm (20"- 120")

Wall thickness: 6.0mm-100mm

Length: up to 70 meters

Features and Benefits

High strength: The weld is fully penetrated and its mechanical properties are close to the parent material.

Large diameter and thick wall: It can produce steel pipes with a diameter of more than 1420mm and a wall thickness of more than 40mm.

Good weld quality: Submerged arc welding has a large penetration depth and few defects, and is suitable for high pressure and high stress environments.

Wide range of applications: It can meet various needs through different materials and anti-corrosion treatments.

Application

Oil and gas: long-distance pipelines, gathering pipelines, high-pressure transmission.

Chemical industry: corrosive medium transmission pipelines.

Water conservancy projects: large water diversion and drainage pipelines.

Structural pipes: bridges, buildings, wind power towers, etc.

Offshore platforms: submarine pipelines, supporting structures.