ERW Steel Pipe

Electric Resistance Welded Pipe (ERW Pipe) uses the resistance heat generated by the current passing through the edge of the metal strip to melt the material locally, and achieve welding under mechanical pressure, and finally form a straight seam steel pipe.

Size Range

Outer diameter: 1/2"-24"

Wall thickness: 1.65-20mm

Length: 3-12m, or according to customer’s requirement

Tube end: Plain End, Beveled End, Treaded

Standard

|

ERW Pipe

|

|

ASTM

|

ASTM A53 B, ASTM A178, ASTM A252 GR.2, A500, ASTM A513

|

|

API

|

API 5L X42/46/52/56/60/70

|

|

EN

|

EN 10204/10217 S235JR,S275JR,S355,S355JR,S355J2H

|

|

EFW Pipe

|

|

Carbon steel

|

ASTM A671,ASTM A672

|

|

Alloy steel

|

ASTM A691

|

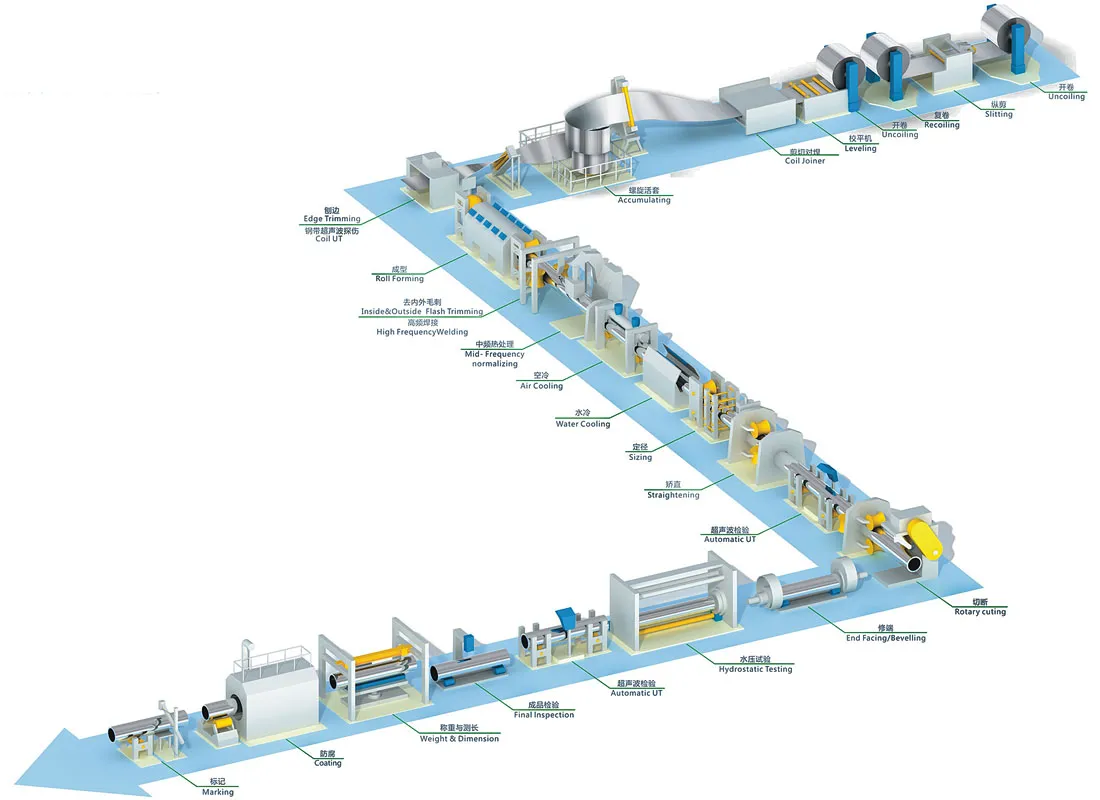

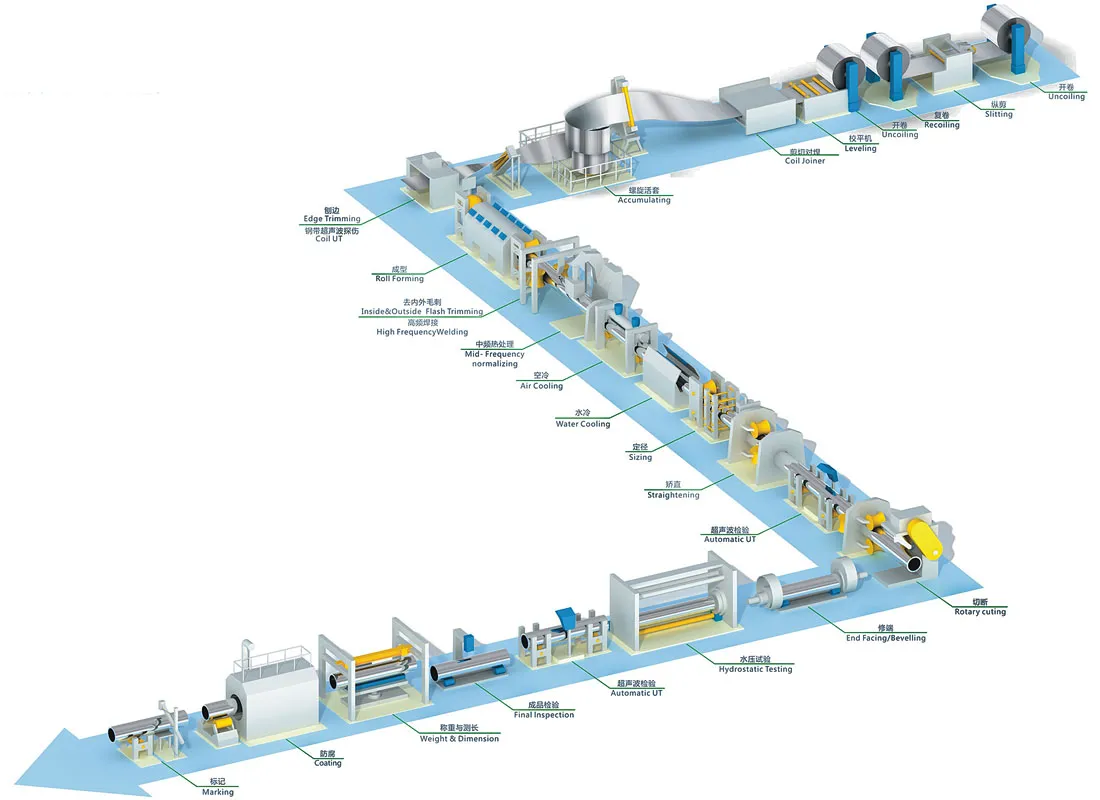

Production Process

Uncoiling and leveling: Unroll and level the steel coil.

Shearing and butt welding: Weld the head and tail of the strip to ensure continuous production.

Forming: The strip is gradually rolled into a round tube through multiple rollers.

Welding: High-frequency current (HF-ERW) or low-frequency current (LF-ERW) heats the edge and pressurizes the weld.

Deburring: Remove excess metal outside the weld.

Cooling and sizing: Control dimensional accuracy.

Cutting and testing: Including eddy current testing, ultrasonic testing, etc.

Application

Energy industry: oil and natural gas pipelines.

Building structures: scaffolding, building support pipes.

Machinery manufacturing: automobile transmission shafts, hydraulic cylinders.

Utilities: water supply and heating pipelines.