Typical valves

Ball valve: DN6~DN1200

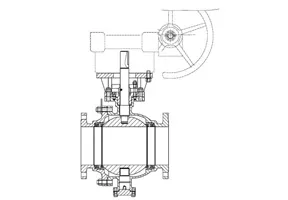

Gate valve: DN15~DN4000API standards: such as API 6D (pipeline valves) and API 600 (steel gate valves) are applicable to the oil and gas industry.

ANSI/ASME standards: such as ASME B16.34 (valve pressure-temperature ratings) are the basic specifications for general industrial valves.

Gate valves are used to cut off or connect media transmission, and are suitable for pipeline systems in petroleum, chemical, thermal power plants and other industrial fields. Gate valves can only be fully opened and disconnected in the pipeline, which means it cannot be used for regulation and throttling.

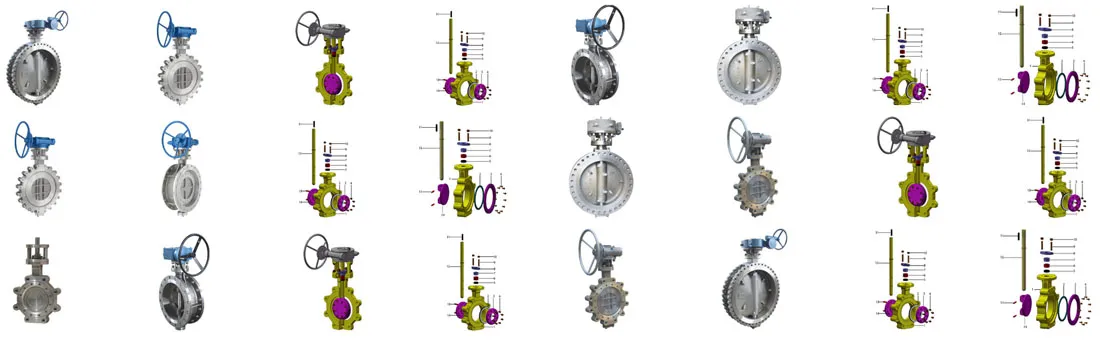

Butterfly valves are widely used in chemical industry, petrochemical industry, marine development, smelting, etc., as regulating and closing equipment. The seat and disc of our butterfly valve employ the most advanced technology to complete the structural design.

|

Types |

Double offset butterfly valves |

Triple Offset butterfly valves |

| Specification |

Anti-static Blow-out proof stem V type packing Zero leakage Ends: Wafer, Lug. Unidirectional/Bi-directional sealing Operation: Lever, Gear, Electric, Pneumatic actuator Bare shaft with ISO 5211 top mounting flange |

Anti-static Blow-out proof stem Fire safe API 607 V type packing Zero leakage Ends: Wafer, Lug, Double flange. Uni-directional/Bi-directional sealing Operation: Lever, Gear, Electric, Pneumatic actuator Bare shaft with ISO 5211 top mounting flange (when specified) |

|

Applicable seat materials |

PTFE RPTFE(15% Glass Filled) RPTFE(25% Carbon Filled) Viton |

Metal with Graphite Metal with PTFE |

|

Pressure |

150LB, 300LB, 600LB |

150LB, 300LB, 600LB |

|

Wafer/Lug |

2”up to 100”, 2”up to 60” |

3”up to 80”, 3”up to 40” |

|

Operator |

2"~4" Lever; 5"~100" Gear, 2"~4" Lever; 5"~60" Gear |

3"~4" Lever; 5"~80" Gear, 3"~4" Lever; 5"~40" Gear |

Globe valves is a linear motion valve and is primarily designed to stop, start and regulate flow. The disk of a Globe valve can be totally removed from the flow path or it can completely close the flow path.

Size:3/4" to 6"

Material:Stainless Steel SS316/Cast Iron /Cast Steel /Forged Steel A105

Working Pressure: 150#, 200#, 800#

Connection Type: 150# Flange End, JIS 10K Flange End, Threaded End (NPT / BSPP) , Welded End Socket Weld

Check valves is a valve referred to the opening and closing parts for the circular disc and by its own weight and medium pressure to block the media flow back.

|

Design |

API594, ASME B16.34 |

|

Testing |

API 598, API6D, EN12266-1 |

|

Face to face dimension |

ASME B16.10 |

|

Ends connection |

ASME B16.5, ASME B1.20.1, ASME B16.25 |

|

Pressure temperature rating |

ASME B16.34 |

|

Marking |

MSS SP-25 |

|

Non-destructive Examination |

VT, PT, RT, UT, MT |